The Importance of Honing Oil in the Honing Machining of a Workpiece

19 Dec, 2022

“Precision and Accuracy” are the two main factors that influence machining productivity. The honing process of a workpiece satisfies the main requirements of the manufacturer on the aspect of product finish by preferring the right honing oil.

Producing a high-precision metal piece is highly complex when it comes to maintaining precision in large volumes. This is not the case when machining with the honing machines.

These machines are highly preferred in the manufacturing of very high-precision workpieces. Honing is the process of polishing the workpiece with the usage of hones.

In most cases, diamonds are attached to the hones strips for an efficient honing process.

Why Honing Oil is used in the Honing Process

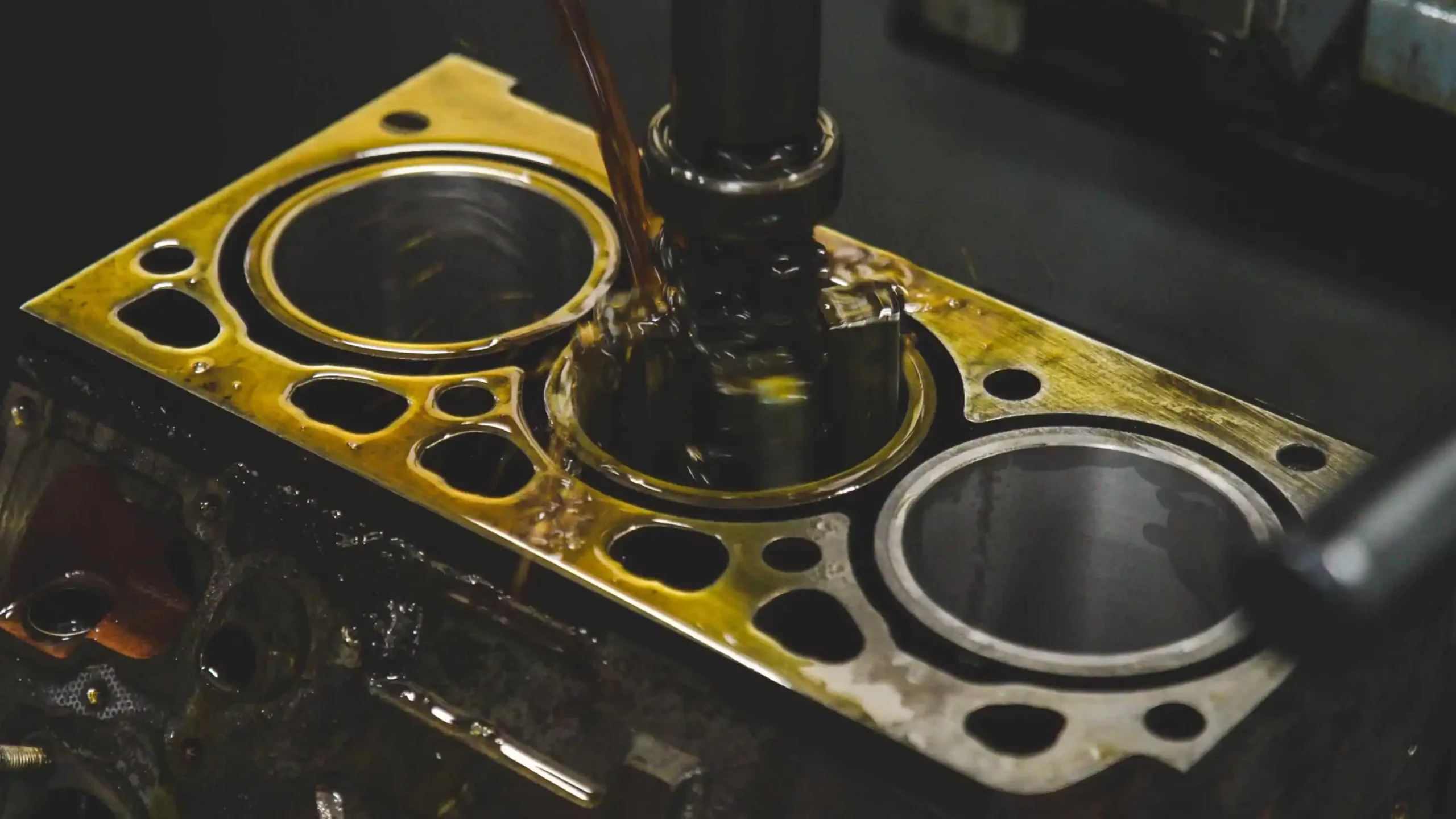

The precision of the workpiece engineered by the honing machine depends on the honing oil used in the process. During the honing process, the chances of creating heat and chip formation on the workpiece to be honed are there.

The development of heat due to the friction between the piece and honing strip reduces the desired product finish. Adding to it, the durability of the honing strips is drastically depleted, which is shorter compared to the estimated shelf life of the hones.

To avoid and restrict the workability of honing strips, Honing Oils are used in the process. Honing oil improves the precision of the honing works and enables the hones to travel in any direction seamlessly.

What are Honing Oils

Honing oils are the lubricants used in the honing process. These oils have very low viscosity and at the same time, it exhibits the properties of lubrication.

Cutting oil enhances the honing operation by increasing the honing finish of the product. The output capacity of the honing machine is decided by the honing oil.

The abrasion/polish of the workpiece has a direct relation to the viscosity and lubrication properties of the honing oil.

Tolerance and Honing Oil

Tolerance is a significant factor that influences the precision honing works of the piece. The higher the tolerance percentage, the lower the product’s workability.

In the case of high-profile engineered products, precision and tolerance play a bigger role. A small deviation leads to a dip in product performance. Every nut and bolt contributes to the functional efficiency of the end product.

Hence, the parts that are processed in the honing machine fit into the drafted design plan of the complete product in the assembly line. Hence, the development of tolerance in one part affects the overall efficiency.

The type and quality of honing oil decide the tolerance level of the workpiece. The use of cutting oil employs the operator to have control over the exact dimensions of the piece.

Stock Removal

Stocks are the fine deposits of the bore material, generally produced during the honing process. These stocks might lead to clogging, when they are unnoticed and not removed prior to the next spindle of the honing process.

As honing oil has low viscosity, when passes under high pressure during the process, remove the stocks of the workpiece material. Though honing oil is a lubricant, it does not form clogs when reacting with the stock deposits of the bore material.

Cutting oil is a secondary material in the production of honing materials, but it has a higher impact on the finishing and superfinishing of the workpiece.

Adding to it, the cutting oil saves the abrasive materials from quicker deterioration.

Honing Oil and Productivity

The minimum and maximum output capacity of the honing machine impact the efficiency of the machine. The operational speed of the honing machine depends on each stage of the process. Hence, the output is defined by the cumulation of process, honing tool, type of honing machines, number of spindles, and honing oil.

As the cutting oil has a role to play in each honing process, thus it is the decision maker of the productivity. The honing oil significantly increases the output capacity and improves operational efficiency.

Honing oil has to be replaced with new oil after a certain period of usage in the production of the honing tool. The replacement of the cutting oil increases the output capacity.

Honing Oil and Precision

The precision of the engineering parts is greatly improved with the usage of honing oil. The oil used in the grinding and polishing of the workpiece assists in achieving the desired precision.

The honing oil chosen in the process has to be based on the work nature of the bore. This factor also impacts the precision and the life of the abrasive material used in the honing process.

There is a chance that honing oil can reduce the precision of the boring piece. This is due to the unmatching properties generated at the time of honing.

The Bottom Line

Honing Oil is one of the major contributors to the precision and accuracy of the honing piece. It ensures the superfinishing of the bore surface, increases the honing stone life, and maximizes the output capacity. Determine the type of honing tool and use the honing oil accordingly for efficient honing machining.